We Provide Support to:

-

Forensic engineering and Insurance companies

-

Law firms and litigation support

-

General manufacturing and plating shops

-

Aerospace and Defense

-

Thermal plants and land based gas turbines users

-

Naval and ground transportation companies

-

Petrochemical and pharmaceutical industry

-

Health and safety

-

Airlines & airports

-

Government departments & agencies

Examples of Failure Analysis Services:

-

Aircraft and gas-turbines components

-

Automotive parts and other debris removed from fires, explosions, accidents

-

Broken glass and ceramic products

-

Corrosion failures including orthopedic implants

-

Damaged axles, shafts, bearings and gears

-

Damaged welds and other joining

-

Failed cables, wires, bolts, fasteners and nuts

-

Failed boilers, heat exchangers and pumps

-

Substandard plated components

-

Particles, fibers and whiskers

-

Substandard raw materials, forging and casting

-

Taps, valves and other defective plumbing

Materials Engineering:

We have extensive experience in selecting the most appropriate metallic and non-metallic materials and processes for your application including:

-

Iron and Steel

-

Non-ferrous materials including super alloys

-

Heat treatment and case hardening treatments (carburizing, nitriding, etc)

-

Welding procedures development and qualifications

-

Recommendations for corrective action in cases of non-conformance or failure

-

Selection and evaluation of specific materials and processes suitable for your system design, including processes and testing protocols for plastics and composite materials (carbon fiber, fiberglass, metallic fiber composites, etc)

-

Development and monitoring programs for technology evaluation

Laboratory Testing & Quality Control:

-

We follow industry accepted methods and procedures such as ASTM, SAE, AMS, DIN, SACMA, etc. as well as specific procedures developed by our clients.

-

We have also developed custom testing procedures to address special requirements.

-

We also provide guidance to clients who may not be knowledgeable as to which testing procedure best suits their requirements.

Common Testing Services:

-

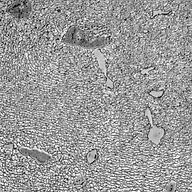

Metallography of wrought steel, castings, forgings

-

Heat treatment evaluation, carburizing and nitriding

-

Metallography of stainless steel and super alloys

-

Metallography of aluminum products

-

Hydrogen pick-up, eutectic melting, clad diffusion

-

Examination of surface treatments

-

Stress Corrosion Cracking (SCC)

-

Susceptibility to intergranular Corrosion (STIC)

-

Coatings thickness measurment

-

Hardness and microhardness

-

Stress Durability (Hydrogen Embrittlement Test)

-

Surface defects: "Orange Peel", Ludder lines

-

Examination of fasteners

-

Examination of welds and welders qualifications

-

Air Contamination and Particle/Fibre Identification

-

Whiskers Control